مسكن

>

vertical mill roll wear

مسكن

>

vertical mill roll wear

منتج

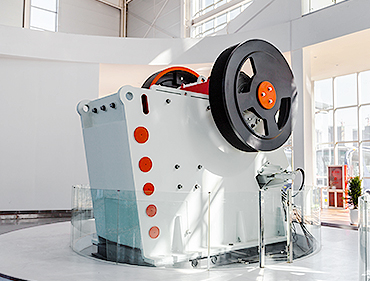

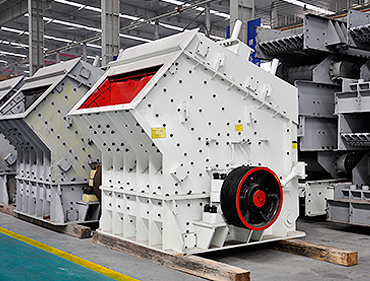

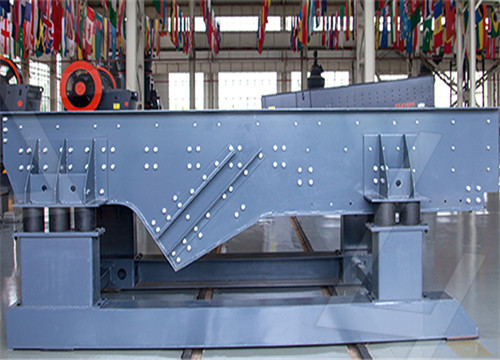

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

vertical mill roll wear

(PDF) Wear of hot rolling mill rolls: an overview

1994年8月1日 An overview of roll materials is given including adamites, high Cr materials, high speed tool steels and compound rolls. Non

Influence of Roll Wear in Hot Rolling of Steel at Hot Strip

2021年8月12日 Roughing mills have horizontal as well as vertical (edger) stands for subjecting steel slab to thickness and width reductions, respectively. While the

Vertical Roller Mills

Vertical roller mills offer supreme grinding with high energy-efficiency. Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs. What’s more, our online condition

Improved performance with advanced wear materials in

Xwin ® is the primary solution to improve wear performance of grinding elements in vertical mills compared to the standard high chromium or hardfacing solutions, while neoX ® will

Spalling Prevention and Wear Improvement of

2015年10月1日 Two new types of rolls, VCR (varying contact back-up roll) and ASR (asymmetry self-compensating work roll), have been developed

Vertical mills Welding Alloys

2023年2月14日 SOLUTIONS FOR VERTICAL MILLS. Vertical mill rolls and tables can be refurbished either on-site (usually in situ) or at one of our Integra ™ workshops to suit the

Vertical roller mill Техноинком

The disadvantage of these mills is the low service life of the grinding elements (rolls and table armor) due to their uneven wear: maximum wear of the bandage occurs at about

Roller Mill Table Liner Wear Bulk-online

2009年7月19日 hi friends, I have a problem regarding the hardfacing of roll table liners and wear segments of MPS vertical roller mills. The mill is being used for grinding of

Tech Profile: A new way to measure roll surface condition

2020年8月10日 In tactile (contact measurement), a standardized diamond tip is pulled over the surface to determine the surface condition. Tactile devices are therefore “all

vertical mill roller wear measurement Grinding Mill China

2013年4月15日 mills, roll wear rates will be greater. Vertical Rotor Mill DFZK DFZK_WEK_2000.PPT Page 3 ? More detailed. Vertical roller mill Wikipedia, the free

Operational parameters affecting the vertical roller mill

2017年4月1日 Separation operation of vertical-roller-mill will be modelled by application of current models. The model shall enable the prediction of the throughput, the particle size distributions around the vertical-roller-mill circuit, the specific energy consumption and in a later stage the wear to be expected in dependency of ore treated.

Coal mill, gypsum mill, clay mill, etc. Pfeiffer

MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil. MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, China. MPS 5000 B mill for raw

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the

Impact Analysis of Roller System Stability for Four-High

2016年6月26日 The F3 mill upper work roller vibration acceleration testing time-domain parameters on field is shown in Table 2.It can be seen that although axial force is less than 1% of the rolling force, roller axial vibration acceleration amplitude is close to vertical acceleration and lateral acceleration, so the axial force (caused by rollers cross)

Fundamentals of Roll Cooling and Control of Flatness at

2021年1月18日 roll bite and in a typical Cold Tandem Mill, work roll temperatures normally fall in the range of 55oC 70oC with strip recoil temperatures and inter-stand strip temperature rarely exceeding 160 oC depending on product. Roll Bite temperatures in slower heavily drafted stands can peak in the region of 300oC, diminishing with the

Flexible milling and grinding solutions that last

Optimal feed material milling and grinding solutions. Carefully crafted to meet your milling and grinding needs, our robust and well-designed solutions are highly adaptable for a range of feed materials. With

Raw Material Drying-Grinding Cement Plant Optimization

Type of mill: Ball and tube mills. Vertical Roller Mills (VRM). Horizontal roller mill (Roll Press) Roller press with Ball mill. Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years. Ball mill is a cylinder rotating at about 70-80% of critical speed on two

Rolling of hot strip and strip defects IspatGuru

2017年1月14日 Elastic deformation of the mill takes place during rolling. Mill spring can be avoided, if stiffer rolls are used which means that the roll material is having high stiffness or elastic constant. Normally elastic constant for mills may range from 1 to 4 GNm-1. Roll elastic deformation can result into uneven strip thickness across.

What Is a Vertical Mill? Career Trend

2019年9月3日 A vertical milling machine's spindle axis is aligned in a vertical manner to the machine's bed. That means that the cutting tool is arranged vertically to shape the metal or other material into the desired form. The vertical mill moves while the part remains stationary. The vertical mill has controlled movements, either mechanically (by hand

Spalling Prevention and Wear Improvement of Rolls in

2015年9月4日 Roll Fatigue. Rolls in the HSM withstand harsh service conditions. Belzunce et al. [] analyzed the highly demanding service conditions of rolls and indicated that these extreme actions led to aggravate wear and fatigue.A typical characteristic of this mill is the rolling schedule of a large variety of the same width steel, which accelerates roll surface

Component wear in vertical spindle mills grinding coal

1996年3月1日 This stone reports on the contribution of a number of material coal properties and machine operating parameters to the wear of vertical spindle mill components. 14 51 102 360 Wear (g/ton) 2.74 7.37 4.8 8.0 M3XSi02 18.6 40.3 70.6 128.3 Table 2. These relationships of mill roll wear rate are similarly linear and of the for

Atlas Vertical Roller Mill NETZSCH GrindingDispersing

2023年3月2日 NETZSCH Ecutec's Atlas Vertical Roller Mills has been developed for more efficient fine grinding of soft to medium-hard materials. ProductsSolutions Dry Grinding Atlas Vertical Roller Mill. The Atlas is a roller air-swept mill designed for continuous operation with minimum maintenance. The fundamental difference between the ATLAS

(PDF) Performance Evaluation of Vertical Roller Mill in

2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject) remain in the

Coupled Vibration Characteristics Analysis of Hot Rolling

2021年6月19日 As shown in Figure 4, M 1, M 2, and M 3 are the equivalent mass of the upper part of mill stand, backup roll, and work roll. J 1 and J 2 are the rotational inertia of electrical machinery and upper rolls system of the rolling mill. K 1, K 2, K 3, and K 4 are the equivalent vertical stiffness. Based on Duffing theory, is the equivalent horizontal

Fundamentals of Roll Cooling and Control of Flatness at

2021年1月18日 roll bite and in a typical Cold Tandem Mill, work roll temperatures normally fall in the range of 55oC 70oC with strip recoil temperatures and inter-stand strip temperature rarely exceeding 160 oC depending on product. Roll Bite temperatures in slower heavily drafted stands can peak in the region of 300oC, diminishing with the

Rolling Mill Stands The Steefo Group

1. Vertical Mill Stand The up-drive type consists of a roll stand, mill spindles, a vertical gear reducer with a pinion stand and a motor. The gear reducer and motor are installed on a concrete frame to protect them from roll cooling water and mill scale. A lifting device is installed under the roll stand to adjust the caliber position to pass

ERSEL Ağır Makine San. ve Tic. A.Ş.

2022年5月24日 Vertical Roller Mills can make drying, grinding and classifying processes all in one compact machine. Vertical Mills has high energy efficiency compared to the other systems. Easily replaceable

Roller Mill Table Liner Wear Bulk-online

2009年7月19日 hi friends, I have a problem regarding the hardfacing of roll table liners and wear segments of MPS vertical roller mills. The mill is being used for grinding of limestone mainly at a rate of 215 tonnes per hour. I would be thankful if anyone can tell me which type (composition) of hardfacing to use to reduce the wear rate. It will be of great help if the

Superior Performance Through Innovative Technology

2019年6月15日 30000 tons of wear parts for vertical mills used. 400 mills retrofitted with improved performance More than 2000 inserted rolls used Roll wear rate (g/t) Table average wear (mm) Table wear rate (g/t) Life. AIAE conventional roll 1181 86000* 24.0 * 6.0 * 39 * 13.5 * 2500. AIAE Sintercast-11 roll 1032 76000 8.5 2.5 11 4.3 >6000 (expected