مسكن

>

ore extraction dissolution

مسكن

>

ore extraction dissolution

منتج

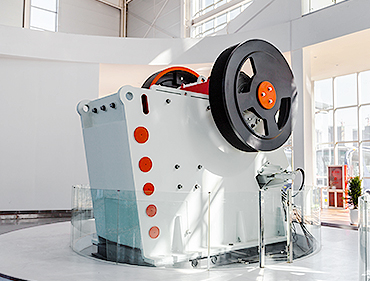

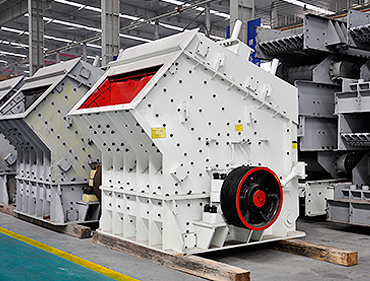

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

ore extraction dissolution

Heap Leaching an overview ScienceDirect Topics

2.1 Leaching. Most copper leaching is done by piling broken ore (∼0.5% Cu) into flat-surface, 3–10m high, 10 4 –10 5 m 2 heaps of ore and then sprinkling dilute sulfuric acid

Extractive metallurgy Wikipedia

OverviewHydrometallurgyMineral processingPyrometallurgyElectrometallurgyIonometallurgyFurther reading

Hydrometallurgy is concerned with processes involving aqueous solutions to extract metals from ores. The first step in the hydrometallurgical process is leaching, which involves dissolution of the valuable metals into the aqueous solution and or a suitable solvent. After the solution is separated from the ore solids, the extract is often subjected to various processes of purification and concentration before the valuable metal is recovered either in its metallic state or as a chemical

Gold Dissolution from Ore with Iodide

2019年3月12日Those strains were incubated in a liquid culture medium containing ore with a gold content of 0.26

PGM extraction from oxidized ores using

PGM extraction from ROM ore by aqua regia leaching was strongly dependent on dissolution temperature and pulp

2013 OPEN ACCESS minerals ResearchGate

extraction of Ni from lateritic ores. microorganisms that are able to accelerate the oxidative dissolution of the sulphide minerals in extremely acidic liquors. The main

PGM extraction from oxidized ores using

2019年11月1日Direct leaching of oxidic PGM ore using different acids yielded relatively low PGM extractions. Leaching in hydrochloric acid achieved extractions of

Heap Leaching Mineral Processing

2016年6月13日The ingress of solutions into ores during leaching, the dissolution of various cooper minerals, and; With 3-inch pieces of ore, an extraction of 80, per cent of

Gold processing Mining and concentrating Britannica

For extracting gold from low-grade ores, heap leaching is practiced. The huge heaps described above are sprayed with a dilute solution of sodium cyanide, and this percolates

Hypochlorite Leaching of Gold Ore Metallurgist

2017年11月8日Raising the leach solution temperature to about 55°C will also enhance the gold dissolution. Extracting gold from an ore required more reagents and longer

Efficient Synchronous Extraction of

2020年6月18日The concentration of the metal element in the leaching solution was determined by the inductively coupled plasma optical emission spectroscopy (ICP–OES

Selective extraction performance of Ni, Cu, Co, and Mn adopted

2022年9月1日The results showed that acidity and Fe 3+ ion affected dissolution of both ores significantly; high valence manganese oxide reduction takes precedence which is in control of the Ni, Mn, Cu, and Co dissolution of the nodule; Ni, Cu, and Co extraction from the nickel ore is a course of sulphide minerals oxidative conversion which significantly

Predicting Optimized Dissolution of Selected African Copperbelt

2023年3月4日The dissolution tests were carried out in 600 mL glass beakers cleaned with distilled water. (2016) Value recovery from Mukondo mine low-grade cobalt ore by heap leaching and solvent extraction. Hydrometallurgy Conference 2016: Sustainable Hydrometallurgical Extraction of Metals, South Africa.

PGM extraction from oxidized ores using

PGM extraction from ROM ore by aqua regia leaching was strongly dependent on dissolution temperature and pulp density, with high temperatures (85°C) and low solid to

Extracting Copper by Lactic Acid from Copper Oxide Ore and Dissolution

2015年7月20日DOI: 10.1252/JCEJ.14WE032 Corpus ID: ; Extracting Copper by Lactic Acid from Copper Oxide Ore and Dissolution Kinetics @article{Deng2015ExtractingCB, title={Extracting Copper by Lactic Acid from Copper Oxide Ore and Dissolution Kinetics}, author={Jiushuai Deng and Shuming Wen and

Extraction of Rare Earth Metal Oxide Inclusion Particles in Steel

Therefore, a stable extraction method for REM oxide in iron was investigated. From the dissolution behavior of Sm2O3, Nd2O3 and Dy2O3 reagents in various eluents, 2 v/v% triethanolamine- 1 w/v% tetramethylammonium chloride-methanol (2%TEA) is most suitable for the extraction of REM oxide.

A Review of the Cyanidation Treatment of

2020年5月21日Most of the gold extraction from ore is accomplished by the implementation of an alkaline cyanide leaching process. The chemical recovery of gold can be

Heap Leaching Mineral ProcessingMetallurgy

2016年6月13日The ingress of solutions into ores during leaching, the dissolution of various cooper minerals, and; With 3-inch pieces of ore, an extraction of 80, per cent of the water-soluble copper was obtained in 6 hours with a 0.5-hour period of drying and a 0.5-hour period of washing, whereas 25 hours was required for a 6.0-hour period of drying

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex.It is the most commonly used leaching process for gold extraction. Cyanidation is also widely used in the extraction of silver, usually

Process analysis and study of factors affecting the lithium

A major step in the conventional sulfuric acid extraction of lithium from mineral ore is the precipitation of lithium carbonate from lithium sulfate media by sodium carbonate addition. Because of the high solubility of lithium carbonate in water and challenges with separating and removing sodium sulfate from the product, this step has a low

Selective extraction performance of Ni, Cu, Co, and Mn adopted

2022年9月1日The results showed that acidity and Fe 3+ ion affected dissolution of both ores significantly; high valence manganese oxide reduction takes precedence which is in control of the Ni, Mn, Cu, and Co dissolution of the nodule; Ni, Cu, and Co extraction from the nickel ore is a course of sulphide minerals oxidative conversion which significantly

A Review of the Cyanidation Treatment of

2020年5月21日Most of the gold extraction from ore is accomplished by the implementation of an alkaline cyanide leaching process. The chemical recovery of gold can be

Solvometallurgy: An Emerging Branch of

2017年4月19日This position stone introduces the reader to the concept of solvometallurgy, the term used to describe the extraction of metals from ores, industrial process

Leaching and solvent extraction purification of zinc from

2021年1月15日The overall Zn recovery from the ore was 71.44% (83.81% Zn leaching efficiency, 3.09% loss in Fe precipitation process, and 88.5% extraction-stripping efficiency).

Extracting Copper by Lactic Acid from Copper Oxide Ore and Dissolution

2015年7月20日Dissolution kinetics of an oxidized copper ore (mainly malachite) in water saturated by Cl2 has been studied. The effect of particle size, flow rate of the gas, temperature and solid-liquid ratio has Expand 15 Dissolution kinetics of malachite in sulphuric acid D. Bingöl, M. Canbazoǧlu Materials Science, Chemistry 2004 90

PGM extraction from oxidized ores using

The PGM dissolution test work was carried out on representative samples milled to 80% -75 μιη using four different acids to establish the best lixiviant system for

Extraction of Rare Earth Metal Oxide Inclusion Particles in Steel

Therefore, a stable extraction method for REM oxide in iron was investigated. From the dissolution behavior of Sm2O3, Nd2O3 and Dy2O3 reagents in various eluents, 2 v/v% triethanolamine- 1 w/v% tetramethylammonium chloride-methanol (2%TEA) is most suitable for the extraction of REM oxide.

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthur-Forrest process) is a hydrometallurgical technique for extracting gold from low-grade ore by converting the gold to a water-soluble coordination complex.It is the most commonly used leaching process for gold extraction. Cyanidation is also widely used in the extraction of silver, usually

Process analysis and study of factors affecting the lithium

A major step in the conventional sulfuric acid extraction of lithium from mineral ore is the precipitation of lithium carbonate from lithium sulfate media by sodium carbonate addition. Because of the high solubility of lithium carbonate in water and challenges with separating and removing sodium sulfate from the product, this step has a low

Heap Leaching Mineral ProcessingMetallurgy

2016年6月13日In leaching a given ore the rate of extraction is not instantaneous but goes on slowly, and the factors of penetration, dissolution, and diffusion, go on simultaneously and not in successive stops. However, these steps can be studied only by segregating them so as to have only one factor entering at a time.