منتج

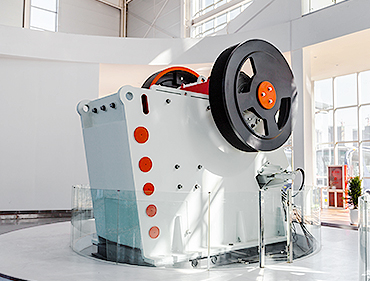

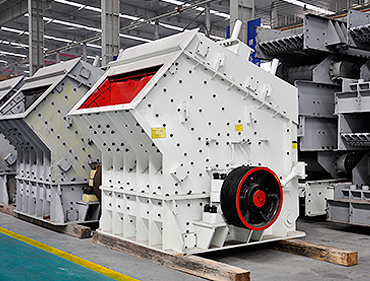

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

Grinding Clay Clinker

[PDF]Breakthrough in Clinker Grinding Massachusetts

2012年11月8日 grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75

Clinker Production an overview ScienceDirect Topics

The basic stage of clinker production is the extraction of raw materials. They are mainly limestone, clay, slate, chalk, and marl. The next stages of production are the preparation

[PDF]Grinding of Calcined Clays and Its Effects on Cement

2017年10月27日 Earlier determination of grindability according to ZEISEL for calcined clay and clinker indicates a lower grindability for calcined clay in comparison with clinker

Influence of Limestone Content and PSD of Components

2019年6月22日 Presence of calcined clay muffles proper clinker grinding, reducing the amount of clinker in the finer fraction, further grinding don’t make any change. Calcined

作者: A. Pérez, Jose Fernando Martirena-HernandezAssessing the effect of alkanolamine grinding aids in

2021年1月10日 Two different calcined clays were used for the preparation of LC 3 blends. First, a natural clay from Chile (Cy) with 60.3% of kaolinite as measured by TGA and a

Influence Grinding Procedure, Limestone Content and PSD

2017年10月28日 Further grinding on LC 3 1:1 increases clinker content at fraction 7 µm < d < 40 µm while decreases at fraction d > 40 µm. The more amount of Calcined clay in 2:1

(PDF) Clinker grinding process and cement

2015年9月16日 Grinding Aids reduce particle re-agglomeration during and after the milling process so improving the yield. Strength enhancers push clinker reactivity increasing the use of SCM in blended cements.

CLINKER GRINDING IN CEMENT PRODUCTION

2019年2月21日 Clinker (in cement industry) is transitional product in cement production. Upon heating mixture obtained from limestone (about 75%) and clay (about 25%) partial melting occurs and clinker granules

HARD CLAY CLINKER FLINT CLAY 200 MESH GRINDING

A Flint Clay powder manufacturer purchased Guilin Hongcheng's HC1500 pendulum mill for hard clay clinker calcined refractory brick (flint clay) grinding powder production line

Influence Grinding Procedure, Limestone Content and PSD

2017年10月28日 Changing calcined clay/limestone ratio, reducing the amount of calcined clay, clinker grinding is improved. By the other hand is possible to find a better compromise between strength and rheology. Increasing limestone amount reduces water demand while is possible to maintain high compressive strength.

[PDF]Breakthrough in Clinker Grinding Massachusetts

2012年11月8日 grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The

(PDF) Clinker grinding process and cement

2015年9月16日 Clinker grinding process and cement properties improvements by additives. nano-clay and nano-magnesium). Nanomaterials were added in small amount (≤1.0%) by dry weight of the

Basics of Cement Sector explained

2023年3月7日 2%-4% of gypsum or calcium sulfate by weight is added to the clinker (1.2) Manufacturing process Lime is mixed with Clay and then burnt in a kiln at temperature of 1400-1450 C.

Hoffmann Green Cement Announces the Granting of the H

2023年3月6日 As a reminder, H-EVA is a 0% clinker cement based on an alkaline ettringitic technology based on activated clay and which is presented in the form of a powder that can be stored in a silo.

Raw mixture for the production of cement clinker专利检索

今 A method for the production of cement clinker which comprises, grinding a composition of lime component 55 to 63 percent by mass, a clay component 23 to 17 percent by mass, a ferrous component 4 to 1 percent by mass, calcium chloride 17.8 to

Why Clinker Matters A Look at its Properties and Application

Clinker is a critical component in the production of cement, the primary material used in the construction industry. Despite its importance, many people are not aware of what clinker is, its properties, and its applications. This blog aims to provide a comprehensive look at clinker, why it matters, and its various uses.

Hoffmann Green Cement Announces the Granting of the H

21 小时之 As a reminder, H-EVA is a 0% clinker cement based on an alkaline ettringitic technology based on activated clay and which is presented in the form of a powder that can be stored in a silo.

Influence of Limestone Content and PSD of Components

2019年6月22日 Presence of calcined clay muffles proper clinker grinding, reducing the amount of clinker in the finer fraction, further grinding don’t make any change. Calcined clay fineness is the main factor that affects water demand and rheology while compressive strength is driven by clinker fineness.

[PDF]Breakthrough in Clinker Grinding Massachusetts

2012年11月8日 grinding seeks to reduce materials from roughly one meter cubes of blasted stone to a size where at least 80 percent of the raw material is less than 75 microns. Finish grinding of clinker and other cement ingredients reduces 25 mm clinker balls to particle sizes optimally ranging from 3 to 30 microns. The

(PDF) Clinker grinding process and cement

2015年9月16日 Clinker grinding process and cement properties improvements by additives. nano-clay and nano-magnesium). Nanomaterials were added in small amount (≤1.0%) by dry weight of the

[PDF]Journal of Physics: Conference Series PAPER OPEN

Comparison between grinding of cement clinker with and without grinding aid (after Fuerstenau, 1990) Figure 1 shows the typical comparison between grinding of cement clinker with and without a grinding aid in a laboratory mill. As discussed in the literature [1,2,4], there was significant effect of using grinding aid in cement grinding.

Cement Analysis IEA

Clinker is the main ingredient in cement, and the amount used is directly proportional to the CO 2 emissions generated in cement manufacturing, due to both the combustion of fuels and the decomposition of limestone in the

Basics of Cement Sector explained

2023年3月7日 2%-4% of gypsum or calcium sulfate by weight is added to the clinker (1.2) Manufacturing process Lime is mixed with Clay and then burnt in a kiln at temperature of 1400-1450 C.

Hoffmann Green Cement Announces the Granting of the H

2023年3月6日 As a reminder, H-EVA is a 0% clinker cement based on an alkaline ettringitic technology based on activated clay and which is presented in the form of a powder that can be stored in a silo.

Raw mixture for the production of cement clinker专利检索

今 A method for the production of cement clinker which comprises, grinding a composition of lime component 55 to 63 percent by mass, a clay component 23 to 17 percent by mass, a ferrous component 4 to 1 percent by mass, calcium chloride 17.8 to

Why Clinker Matters A Look at its Properties and Application

Clinker is a critical component in the production of cement, the primary material used in the construction industry. Despite its importance, many people are not aware of what clinker is, its properties, and its applications. This blog aims to provide a comprehensive look at clinker, why it matters, and its various uses.

Hoffmann Green Cement Announces the Granting of the H

21 小时之 As a reminder, H-EVA is a 0% clinker cement based on an alkaline ettringitic technology based on activated clay and which is presented in the form of a powder that can be stored in a silo.