مسكن

>

crushing mining processes research and diagram iro

مسكن

>

crushing mining processes research and diagram iro

منتج

أكثر من 30 نوعًا من المنتجات تغطي التعدين وسحق البناء والطحن الصناعي ومواد البناء الخضراء وغيرها من المجالات

crushing mining processes research and diagram iro

(PDF) Research into the crushing and grinding

2019年1月1日 Research into the crushing and grinding processes of iron ore with its simultaneous effect by mechanical load and electric field of ultra-high frequency Authors: Petro Shcherbakov Dnipro...

Life cycle assessment of iron ore mining and processing

2015年1月1日 Crushing and screening is typically the first step of iron ore beneficiation processes. In most ores, including iron ore, valuable minerals are usually intergrown with

Research into the crushing and grinding processes of

process of mechanical crushing and grinding of iron ore. Functions of absorption and dispersion amplitudes are obtained from the vector equation of a harmonic oscillator.

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A

(PDF) Life cycle assessment of iron ore mining

2015年12月31日 Mining of iron ore is a highly capital- and energy-intensive process. Life cycle assessment (LCA) of the mining and mineral

(PDF) SIZE REDUCTION BY CRUSHING

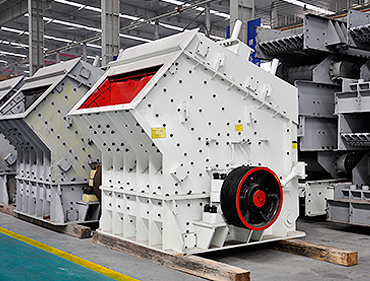

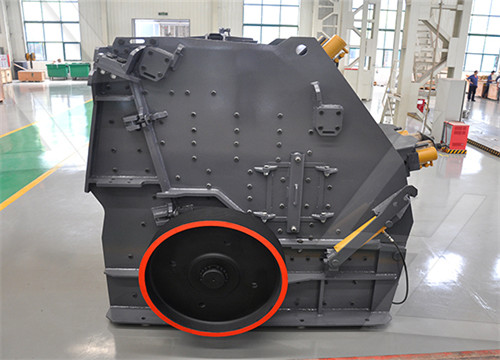

2017年3月4日 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by...

Iron Mining Process Equipment Flow Cases JXSC

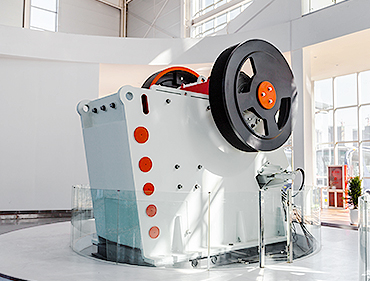

2023年2月22日 Iron Ore Mining Process 1. Large raw iron ore for primary crushing are fed into the jaw crusher by Plate feeder and are reduced to 8 inches or smaller. After first

Crushing Mining Processes Research And Diagram Iro

iron ore process flow diagram excellent mining crushing machinery products or production line design the company is committed to building the Chinese brand mine crushing and

crushing crushing mining processes research and diagram

Copper Mining and Processing: Processing Copper Ores Superfund. This process uses a series of physical steps and high temperatures to extract and purify copper from copper

crushing mining processes research and diagram iron

Aug 2 2016 crushing and screening mining diagram Iron ore crushing and Galvanising global resources decades of copper mining crushing and Copper Gold Mining Process From

Applied Sciences Free Full-Text Research on Particle Size

2023年2月5日 To study the particle size distribution and energy variation law of hard coal under a load, an impact compression test of hard coal specimens under different impact loading conditions was carried out using a Φ50 mm diameter Separate Hopkinson Press Bar (SHPB) test system. We implemented the theory of dynamic impact energy of rock to

The six main steps of iron ore processing Multotec

Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

The focus of this research is the crushing and screening

The capability of process simulation to replicate crushing plant performance and implementation in fullscale plant design and operation has increased over the past couple of decades [9, 10, 20,21

11.19.1 Sand And Gravel Processing US EPA

2015年9月10日 Mining methods depend primarily on the degree of cementation of the rock. In some deposits, blasting is required to loosen the material prior to processing. The material may undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing.

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

crushing mining processes research and diagram iron

Eco efficient and cost effective process design for magnetite iron ore . Iron ore has a special place in the global mining industry judging by the Figure 2 Liberation curve for the study case The cost associated with Primary crushing followed by wet SAG or AG milling and ball or pebble It was assumed that there were no restrictions on spatial layout and that the

Evaluation and Risk Analysis of Open-Pit Mining

2019年4月10日 Mining of raw materials is a process that consists of several stages. In open-pit mining, material with high compressive strength is extracted by drilling and blasting and material with low compressive

Applied Sciences Free Full-Text Research on Particle Size

2023年2月5日 To study the particle size distribution and energy variation law of hard coal under a load, an impact compression test of hard coal specimens under different impact loading conditions was carried out using a Φ50 mm diameter Separate Hopkinson Press Bar (SHPB) test system. We implemented the theory of dynamic impact energy of rock to

Fig. 1 Process diagram for the primary crushing

According to [10,11], the main reliability assessment methods that also may be use for production processes analysis performance mostly include: Failure Mode and Effect Analysis (FMEA), Fault...

Simulation experimental investigations on particle

2023年3月5日 1.Introduction. Solid backfilling coal mining (SBCM) has already widely used in coal resources mining and other aspects, and is an important technical means to achieve green mining [1, 2].In addition to efficient disposal of coal mine wastes (e.g., gangue and fly ash), SBCM can reduce the land occupation caused by the accumulation of gangue [3],

11.19.1 Sand And Gravel Processing US EPA

2015年9月10日 Mining methods depend primarily on the degree of cementation of the rock. In some deposits, blasting is required to loosen the material prior to processing. The material may undergo primary crushing at the mine site before being transported to the processing plant. Figure 11.19.1-2 is a flow diagram for industrial sand and gravel processing.

Crushing in Mineral Processing

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock ( geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for

crushing mining processes research and diagram iron

Eco efficient and cost effective process design for magnetite iron ore . Iron ore has a special place in the global mining industry judging by the Figure 2 Liberation curve for the study case The cost associated with Primary crushing followed by wet SAG or AG milling and ball or pebble It was assumed that there were no restrictions on spatial layout and that the